EVERSPRING heating Element

MoSi2 heating elements are applied for various electric furnaces. The products have the capabilities to resist to oxidation and repair automatically, suitable for continuous using in all kinds of oxidizing atmospheres.

MoSi2 heating elements are shaped in hot-working process, which keeps the base material in good tenacity and plasticity at high temperature with below advantages.

Excellent material properties allow it to be produced in any special shape and any dimension.

Special design on welding spot to ensure long product life.

Good appearance quality and high mechanical strength.

Excellent performance in no-oxidizing atmosphere electric furnaces with special technology applied.

- Custom products available according to customer's drawings or samples

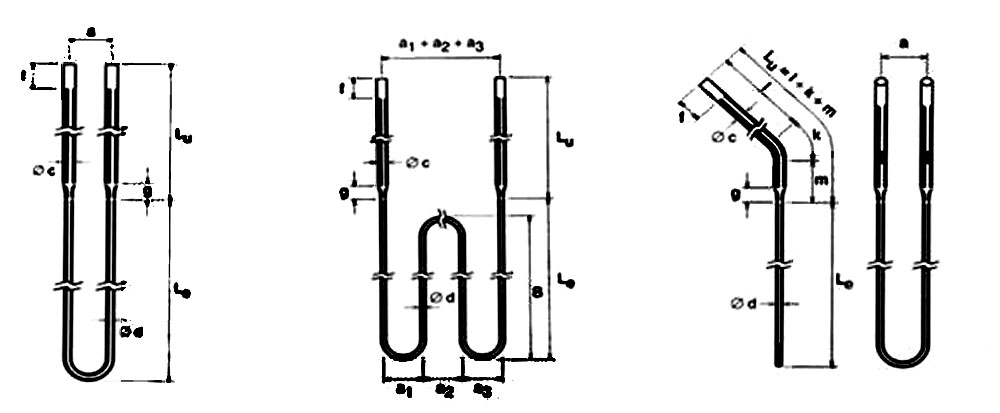

Heating element catalogue

Notes: Above are standard products,we may produce any special shape and any dimension to meet

the customer requirement

Heating element DIMENSIONS

Product Physical Property DATA

KEY PERFORMANCE iNDEX - iNDICATORS IN DIFFERENT ATMOSPHERE

Notice: it is no good to use Molybdenum Silicide Heating Element for Long-term within a range of 400-700℃,otherwise the element will be pulverized by the strong oxidation from low temperature

Recommendations for Heating Element use & maintenance

.

Recommendations for Heating Element before Use

Before starting up a furnace for the first time or a furnace without use for long-time, it is necessary to dry it out. Normally the drying our temperature is 100-200℃. The drying out period of small furnace is only a few hours while big furnace need long-time to dry out.

It is necessary to open the furnace door for ventilation.The door should be opened slightly when temperature arises till it exceeds 1000℃,then close the door completely and allow the furnace to run up to full temperature at operating voltage.

.

Recommendations for Furnace Starting-up

To avoid high current surges which may cause damage. The recommend starting procedures as following

.

Recommendations for Heating Element in Use

MoSi2 Heating Element is a dense ceramic material. It is hard and brittle at room temperature and impact strength is low, which means it should be taken care of during the process of transportation and installation in case of damage

When MoSi2 Heating Elements continuously operate in oxidative atmosphere, the element temperature must not exceed max. element temperature. (refer to product information)

MoSi2 Heating Element must avoid long-term working in 400-700℃,otherwise the element will be damaged by the strong oxidation from low temperature.

Notes: If any inquiry,please contact us via sales@everspringceramic.com for support.